In many enterprises in industries such as chemical and petroleum, due to the flammability and explosiveness of raw materials, intermediate products, and finished products in various links such as production, storage, and transportation, coupled with the complex and variable chemical process flow, high temperature, high humidity, high pressure, and deep freezing, there may be or may be the overflow of flammable liquids, vapors, and gases under normal or accident conditions.

When these flammable media are mixed with air at a certain concentration, an explosive mixture is formed, and the space occupied by the explosive mixture becomes a hazardous environment with varying degrees of explosion. Below, we will briefly describe the classification of hazardous areas in explosive gas environments and the selection requirements for electrical equipment.

1. Confirm the zoning of the explosion-proof area

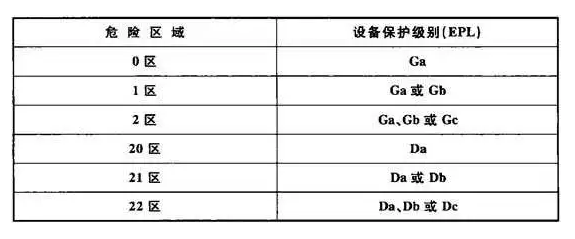

(1) Different types of releases and release durations correspond to different levels. Explosive gases correspond to zones 0, 1, and 2, while explosive dust corresponds to zones 20, 21, and 22.

(2) Different levels correspond to different levels of electrical equipment protection (EPL). Taking explosive gases as an example, in general, the explosive gas environment is mainly Zone 2, with a small amount of Zone 1. Zone 1 mainly refers to the area within Zone 2, or some special release source requirements (such as Zone 1 within 15m of the tank truck's closed injection port).

(3) Corresponding to Zone 0 of explosive gas environment, the equipment protection level of electrical equipment is Ga, while Zone 1 of explosive gas environment is Ga, Gb, Zone 2 of explosive gas environment is Ga, Gb,Gc, Taking into account all factors, the equipment protection level can be selected as Gb, and similarly for explosive dust environments, the equipment protection level can be selected as Db.

The specific selection of protection levels for electrical equipment in explosive environments is shown in Table 1:

2. Select explosion-proof structures for different electrical equipment based on their protection levels

There are several types of general electrical explosion-proof structures:

(1) Explosion proof type: capable of withstanding sparks generated when flammable substances enter the shell or when specified faults occur, and cannot ignite flammable gases or dust;

(2) Increased safety type: Measures are taken to prevent internal and external hazards for electrical equipment that does not generate arcs or sparks under normal working conditions;

(3) Positive pressure type: Electrical equipment that maintains the internal air pressure higher than the external pressure to achieve safety.

Common electrical equipment, such as distribution boxes, lighting fixtures, and motors, can be explosion-proof; Explosion proof junction boxes and wiring boxes can be of increased safety type.

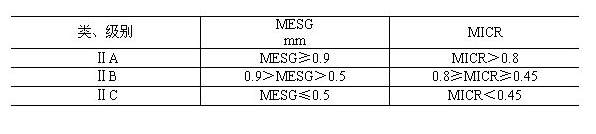

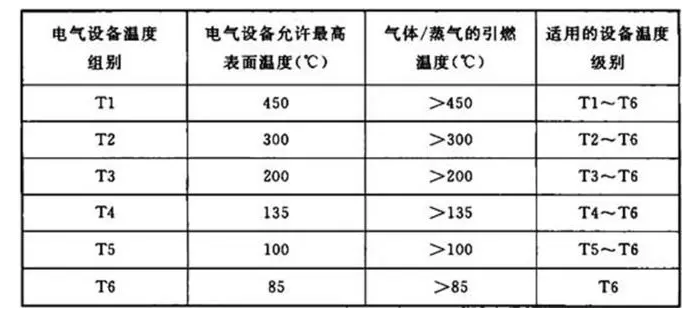

3. Determine the level group of the explosive gas or dust mixture based on its specific composition

Each explosive gas can be classified according to the maximum test safety gap or minimum ignition current ratio (see Table 2), and grouped according to the ignition temperature (see Table 3). For explosive dust, the classification and grouping are no longer required, but the explosive dust is classified and labeled with the highest surface temperature of the equipment.

Table 2 Classification of Explosive Gas Mixtures

Table 3 Ignition Temperature Grouping

When multiple flammable substances are mixed, the selection should be based on the level and group of the explosive mixture after mixing. When there is no data available and it cannot be determined through experiments, it can be classified as a higher level and group.

When there are both explosive gases and dust present in the explosion-proof area, both requirements should be met simultaneously. When dealing with combustible gases or dust that are not traceable and cannot be determined through testing, reference can be made to other explosive gases or dust with the same chemical structure.

|

||||||

|

||||||